![]()

Energy Saving Device Design and Production

Zone1Hull resistance reduction/Improvement of stern flow/Recovery of propeller loss

Zone2Improving propeller efficiency

Zone3Recovery of propeller loss

/Rudder performance improvement

Eco-Stator

Pre-swirl type energy saving device categorized in Zone 1.

Over 300 vessels have installed.

Composite Eco-Stator

Pre-swirl type energy saving device categorized in Zone1.

(Jointly developed with Nakashima Propeller Co., Ltd.)

Eco-Nozzle

Semi-duct type energy saving device categorized in Zone 1. A VLCC has installed.

Rudder Bulb and Rudder Fins

Rudder Bulb type energy saving device categorized in Zone3.

(Jointly developed with Nippon Yusen Kaisha.)

Eco-Stator

Rudder Bulb and Rudder Fins

Composite Eco-Stator

Eco-Nozzle

Eco-Nozzle

By installing them individually or in combination to newbuilding and existing ships,

fuel consumption is reducible by 3~7%.

They performs various energy-saving effects such as constant ship speed, saving

fuel oil and reducing vibration.

An energy saving device installed to Stern tube

What Eco-Stator is

Fuel oil consumption is reducible by 3-4% as energy-saving efficiency.

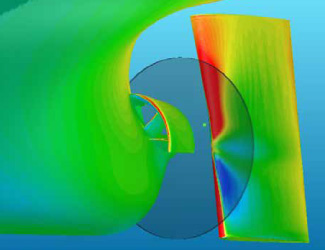

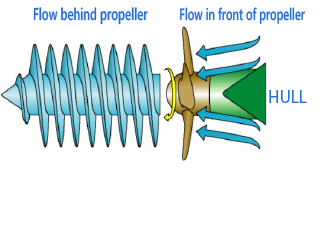

Eco-Stator is one of pre-swirl type of energy saving devices installed in front of propeller,

which has four or five stator fins fixed radially around stern tube and upper side of propeller

shaft.

It works as to rectify a water stream flowing around the stern and helps the propeller to

enhance its thrust at minimized propulsion main engine output.

(Trademark registered. ISO9001 certified.)

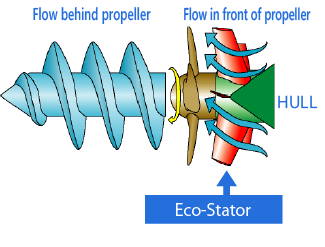

Eco-stator Principle

Energy saving devices to improve the rotational flow behind propeller have been developed

since more than 100 years ago. By arranging of Eco-Stator in front of a propeller, an inflow into

propeller is rectified, thus slipstream is lessened.

Overlooking of stern

Without Eco-Stator

With Eco-Stator

Advantages of Eco-Stator

-

- Fuel oil consumption is saved by 3∼4% keeping ship speed.

- Ship speed is increased with keeping fuel cost.

- Stern vibration is abated by rectified inflow into propeller.

- Propulsion performance of existing ships with propeller which is not able to absorb engine output efficiently is improved.

- Effectiveness is shown for both coastal ships and ocean-going ships.

Contact us for more information

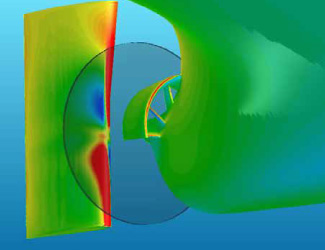

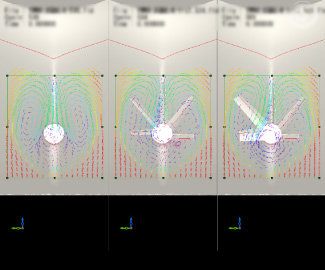

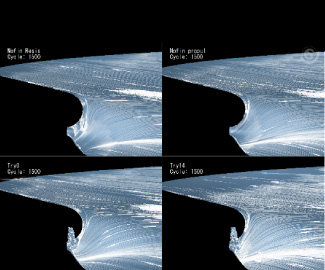

Eco-Stator is designed based on an extensive database of full scale ship and tank test results.

Predicting the flow at the stern end is essential when designing the installation figures.

CFD calculations and tank tests are helpful for designing the best configulation and installation.

CFD

CFD

CFD

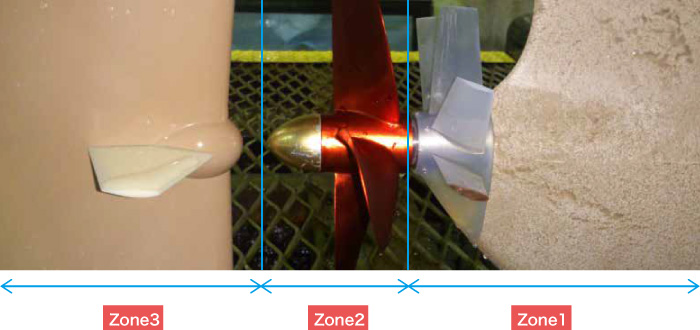

Tank Test

Tank Test

New

building

- Comparison of performance with and without Eco-Stator by tank test.

- Comparison of performance between the prediction and the results of sea trials when Eco-stator is installed.

- Comparison of service record(Ablog) and sea trial results between same type ship without Eco-Stator and an object ship with Eco-Stator.

Retrofit

- Comparison of performance with and without Eco-Stator by tank test.

- Comparison of sea trial performance before and after installation of Eco-Stator.

- Comparison of service record (Ablog) with and without Eco-Stator.

For more information on Eco-Stator, see our product information page.

Visit here.

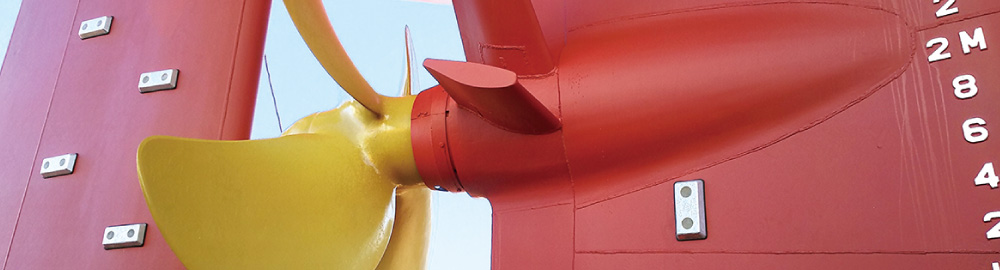

Rudder Bulb and Rudder Fins

Rudder Bulb type of energy saving device is categorized in Zone 3.

The device to recover the energy loss due to propeller and improve rudder performance by

installing uniquely designed round-shaped bulbs and fined to rudder surface behind bosscap.

(Patented)

Principle of Rudder Bulb and Fins

Comprehension of inflow into propeller

Rudder Bulb and Fins are installed on rudder surface to capture rotational flow generated by

propeller and rectify the flow behind propeller, while at the same time helping the

performance of rudder itself to convert loss caused by propeller into propulsion.

Efficiency due to Rudder Bulb and Fins

- Fuel oil consumption is saved by3∼4% with keeping ship speed.

- Rudder performance of existing ships is improvable as it is installed on rudder surface.

- Rudder Bulb and Fins can be installed individually or in combination with other energy-saving devices.

Interaction with Other Energy-Saving Devices

In combination with Eco-stator, flow field around stern is optimized. This combination

performs even greater efficiency.

Composite Eco-Stator

Principle of Composite Eco-Stator

Eco-Stator made by GFRP(Glass Fiber Reinforced Plastic) and steel.

Advantages of GFRP

・Partly composite with steel for superior corrosion resistance and weight reduction while

ensuring strength.

・Realizes the fabrication which was difficult to form with steel, improves the performance

of the energy-saving device in design.

Energy Saving Efficiency by Composite Eco-Stator

- It is confirmed from the service data that fuel oil consumption is reduced by about 3% in service after the installation to a slender type ship at the identical main engine and similar ship speed.

Eco Nozzle

Principle of Eco Nozzle

An energy-saving device categorized in Zone 1.

Fuel oil saving efficiency

【Model of Eco Nozzle for Tank Test】